Development of PFA based concrete with Supermix Concrete, Malaysia.

Supermix was one of the first companies in Malaysia to develop fly ash based concrete for mass pours and to improve flow and pumpability.

Some examples of Cementitious based projects and experiences are highlighted below:.

Supermix was one of the first companies in Malaysia to develop fly ash based concrete for mass pours and to improve flow and pumpability.

ScotAsh is a rare example of a joint venture between a Utility and a Cement Manufacturer. ScotAsh was the first plant outside of the USA to install STI carbon separation ensure quality of the fly ash. A sophisticated blending and packing plant has allowed ScotAsh to cater for a wide range of markets including the oil sector and waste stabilisation. ScotAsh has won many environmental awards including The Queen’s Award for Innovation in 2005 and Queen’s Award for the Sustainable Development” in 2008.

Fly ash based cements were produced for both the ready mix and packed product markets. Fly ash can help improve durability, flow and workability of concretes and mortars.

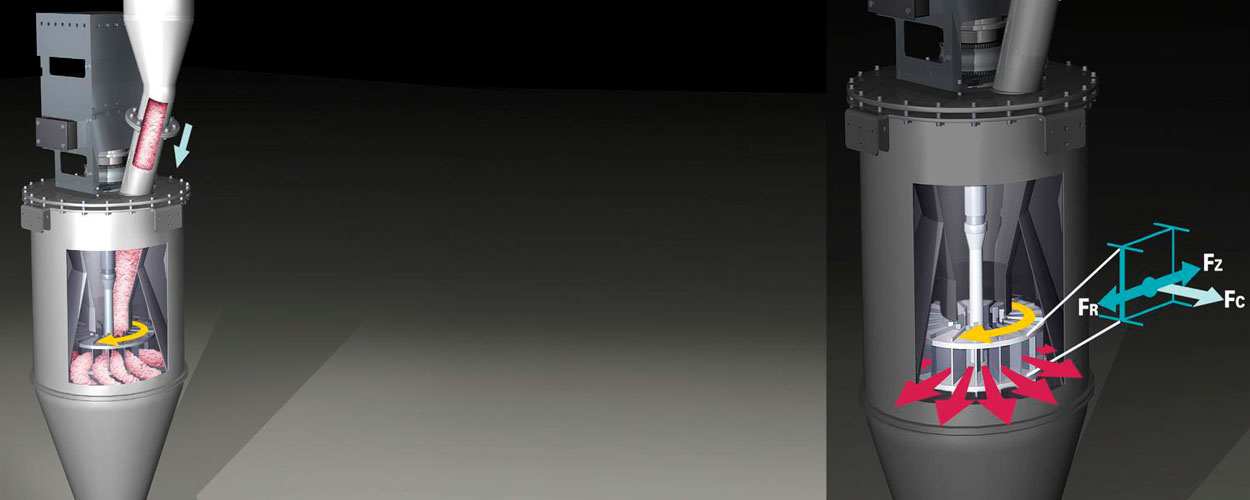

EDF Energy financed and a Lafarge managed project to install STI carbon separation together with high carbon return to the coal belt for re-burn. Project was designed to maximise use of existing infrastructure.

First installation of an integrated carbon and ammonia removal plant with high carbon return system outside of USA.

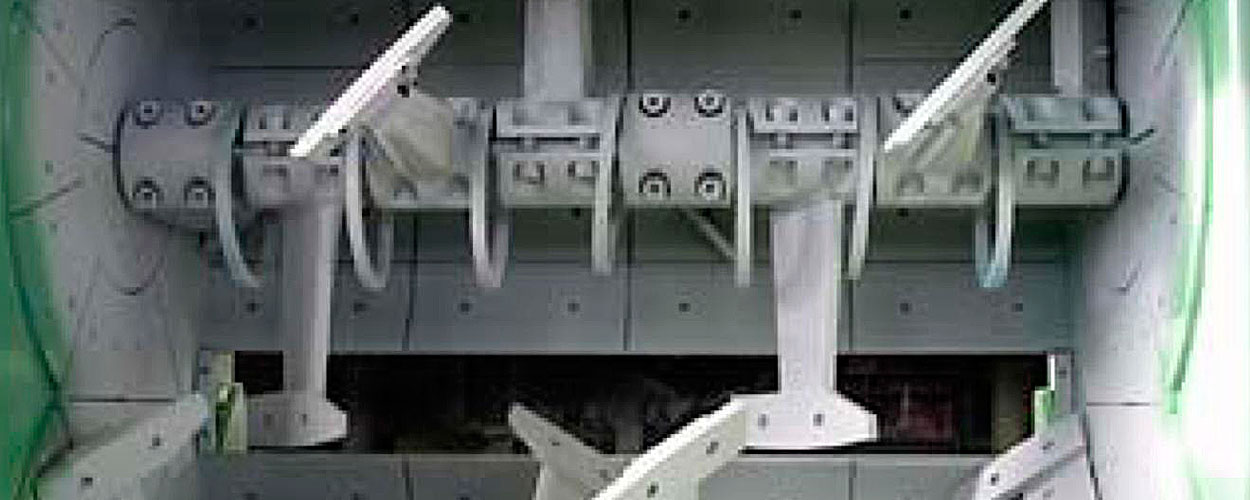

High shear mixers / Schenk Coriolis blending / Clyde Dense Phase blending have all been evaluated for the blending of cement with fly ash and slag. Choice is very much subject to market requirements.

In the case of fly ash, it is rare that there is adequate storage within the supply chain to accommodate fluctuations in supply and demand. This places a premium on seeking low cost storage options. Projects in Africa and the Middle East often require fly ash as or ground slag supplied in jumbo bags using containers.

Increasing demand for cementitious materials has led to a significant growth in the trading of fly ash and slag. Costly mistakes can be made if there is not a good appreciation of where all the risks lie within the supply chain. The dynamics are very different to the trading of manufactured products such as cement and clinker.

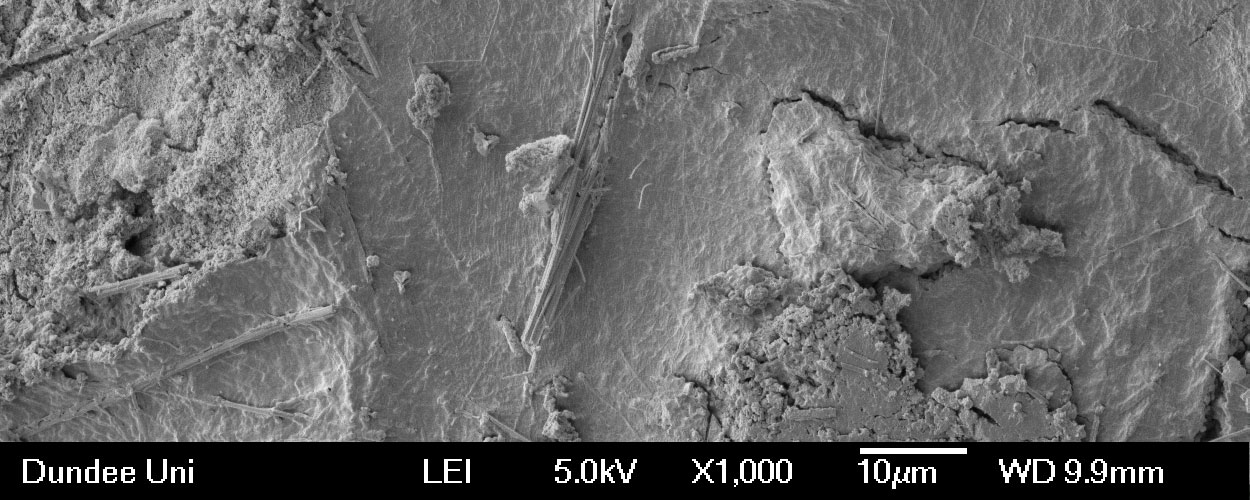

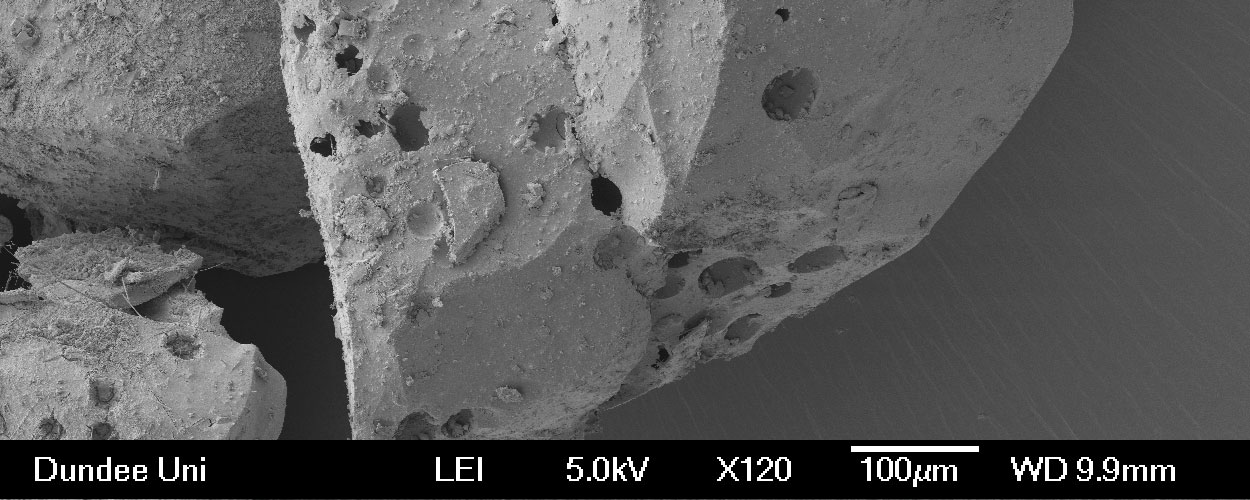

It is critical to have a good understanding of the physical and chemical characteristics of fly ash and slag before committing to long term contracts or for the supply to major projects. There is also a significant growth in Circulating Fluidised Bed Power Stations where the ash can have significantly different properties which may mean the ashes are more suitable for waste stabilisation rather than cement applications.